Another construction option for the resonator is the choice of body with concave strips. This constitutes a further tool in the hands of the instrument maker which allows them to draw greater tone from an even more “living” body as the wood strip acts as a reflection with a lower natural resonance.

Enhancing the contribution of the body to the final sound effect has been addressed by the luthiery of the past centuries. One method that is proposed by the European tradition is the construction of the duo of the Renaissance lute. This is recommended for the hollowing out of the outer side of each tree by removing a mass of wood.

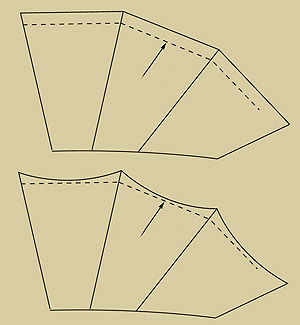

In the drawing, one can see that the wood strip is thinner in its centre which allows it to respond more easily to the vibrating top. This method reached us in its highly developed form through the work accomplished over the centuries on very expensive mandolins.

Unfortunately however, the amount of work and the knowledge required for the correct implementation of the concave strips of the Renaissance lute constitute, I believe, factors that severely circumscribe the more wide spread implementation of this technique which – in our opinion – leads to remarkably pleasing aesthetic results both for the ear as well as for the eye.

New stable neck for musical instruments and method of construction Diploma of Patent No. 1008623 from Organization Of Industrial Property to Spourdalakis Christos son of Georgios & Katos Ioannis son of Panagiotis. International Classification (INT.CL8): G10D 3/00, G10D 1/00.

This specific patented method of our workshop provides a stable neck, virtually unaffected by moisture changes and ensures rigidity for an unlimited period of time. You can learn more about the technique in the subtitled video.

In the related video you can watch, among other things, the process of the Interior body being covered with golden layers 12K.

This is a hardwood with a limited ability to contract, few grains and no warping after being dried. It is quite elastic but it cracks easily. It is difficult to work with, although easier than one would have thought, given that it is a hardwood. It is invulnerable to insects and fungi and is also resistant to water.

Unfortunately, this wood is much more difficult to find than it was in the past, since it has been under legal protection for the last few decades under laws protecting rare flora. Its harvesting is forbidden and the very few pieces that are commercially available are therefore very expensive and must be accompanied by certifications of their origin, which guarantee that they were harvested prior to the ban.

The other source is illegally harvested jacaranda, the value of which as a prohibited and rare variety, one can only imagine. However, the sound of Jacaranda is unsurpassed and is the first choice in the construction of instruments. This is so because this wood, as in the case of other Brazilian rosewoods, offers a clear and brilliant primo, that is, it fosters the clarity and sweetness of the higher registers of the instrument without taking away from the deep bass registers in the least. In addition, it is also the first choice of wood for classical guitars which are instruments that require a much broader range of sound.

We construct instruments from Jacaranda on order only and it is likely that the number of these instruments will be very limited. The small quantity of this material that we have at our disposal comes from very old legal harvesting.

These days, when we speak about rosewood, we are almost always speaking about Indian rosewood, because it is the only rosewood that is actually available on the market albeit with some limitations. Its color varies from light to dark brown, which lends an aesthetically pleasing appearance to the instrument.

The ability of rosewood to bend, its natural resonance, and as we saw, its particular density and hardness, make it appropriate for resonating the vibrations of the top and for this reason, experience has demonstrated that it produces instruments with excellent sound. This is the case in the construction of guitars in which rosewood is used almost exclusively and over the years I have seen it to be the case as well as in the construction of bouzoukis.

Another variety of rosewood is Pernambuco, which has a pleasant Indian red or orange color. This is an extremely expensive wood, the harvesting of which was also recently prohibited (in 2005 I believe). In my personal experience, Pernambuco far surpasses the other available varieties of rosewood. Only a limited number of instruments are available from this type of rosewood.

Mulberry is another kind of traditional wood. This wood lasts for a long time. It can be bent with the use of steam and is easy to work with. It has a density of 550-700 kg/ m3. Mulberry is much better wood than walnut, in my opinion. It offers a warm, folk sound. It is normally used for the construction of smaller concave instruments such as the baglamas and the Tzouras. However, pieces of mulberry are also used for bodies with wood strips and the results are good.

This wood is also famous by other names like Amazique or Amazoue, Mozambique and Shedua. The wood comes from a medium to small sized tree, which is native to tropical West Africa. The tree is an exotic hardwood species that belongs to the genus Guibourtia. Other species included in this genus include the Tiete and Bubinga rosewood.

Ovangkol heartwood often appears with varied coloration that ranges from yellowish to reddish-brown. It also has darker stripes of dark brown and gray, and sometimes black. The sapwood is white and pale, sometimes yellowish or grayish. The texture of the wood is medium and has small pores, with a slightly interlocked grain that is typically straight. It has attractive ripples and curls in the grain most of the time, which makes the wood look very attractive. When freshly cut, the wood has a very distinct and often unappealing smell. It vanishes as the wood dries.

Often it is used for making acoustic instruments with very interesting designs and tone.

Maple grows in central Europe, from the Balkans to the foothills of the Alps. It has a whitish to slightly yellow color. It has medium elasticity and can be worked easily and cleanly. It is very sensitive to fungi and is adversely affected by insects. Its density and degree of hardness differ significantly from region to region. Traditionally the bodies of the bowed instruments in the violin family are made from maple.

The wide range of techniques available to us allows the choice of the appropriate piece of wood and the degree of hardness so that the body will interact as harmoniously as possible with the top to produce optimal results. At times, maple also displays some aesthetic characteristics in its spotted form, the bird’s eye, which is hard and aesthetically pleasing. The ripples that sometimes appear in the flame maple (the Greek commercial name is Moare) are another unusual feature of this wood. These naturally occurring aesthetic quirks of the wood have no impact on the sound; they simply aid us in making the end result more pleasing to the eyes.

Walnut is grown in Asia Minor and can be found all over Greece. The wood is fairly hard, elastic and is quite durable with regard to cracking and when struck. It is of medium weight (600-750 Kg/m3) and is lightly grained. Therefore, it is very easy to work with. It has a light golden brown or white colour. Its resistance to fungi and insects is average and it can be dried easily, though slowly. in the open air without damaging the wood. Most bouzoukis have been constructed from walnut, either unpainted, or painted black.

Unpainted walnut dominated in the pre war years and immediately post war years, while painted walnut dominated from the 1950s onward. Due to its special qualities, this wood results in a sound that is considered characteristic of the bouzouki. In my opinion, instrument makers continued using walnut because it really was among the best of the indigenous varieties and commercial access to better and more rare materials was very limited in Greece in the past. Furthermore, musicians at that time could not afford rosewood or ebony which for example would have raised the cost of an instrument prohibitively. That is to say, it would have been much more expensive than using walnut which one can find easily in a Greek village. It is widely believed that walnut is the appropriate wood for a bouzouki because it has been used to make excellent instruments. In my opinion, this does not necessarily mean that it is the ideal wood, simply that walnut has been given many more opportunities to be used in the making of this instrument than any other wood. Even today, the vast majority of bouzoukis are made from walnut. Perhaps only one or two out of ten bouzoukis are constructed from all the other possible woods.

So, walnut has been given many more opportunities for the color of its sound to be identified with the sound of the bouzouki. When considering the acceptability of walnut, it is the unpainted one rather than the one that has been painted black that should be chosen. The latter is produced when pigment is applied in an acidic environment at 100’ C, which damages the cellular structure of the wood. This results in a susceptibility of the body to breakage and in essence the wood is “dead” after it has been removed from the mold. However, in order to satisfy some of our customers who insist on this particular tradition, we offer bouzoukis with bodies constructed from walnut that has been painted black.

A further possibility that we offer is the combination of two types of wood. We have seen instruments in which the body is made with strips from two kinds of wood placed side by side (usually maple and some type of dark wood) and in this way a kind of striped effect is achieved. When we choose the use of two kinds of wood, in addition to the aesthetic element, we must also take the acoustic effects into account in our choice, since the impact of the body on the sound is proportional to the quality of the materials selected.

Address

Neorion 27 &

Eleftheriou Venizelou,

Prophet Elias,

185 33 Piraeus

Phone number

(+30) 210 4223 056